Various coil winding wires, double wire, multi wire, cake wound special inductance, parallel enamelled wire, various specifications customized

Product Description

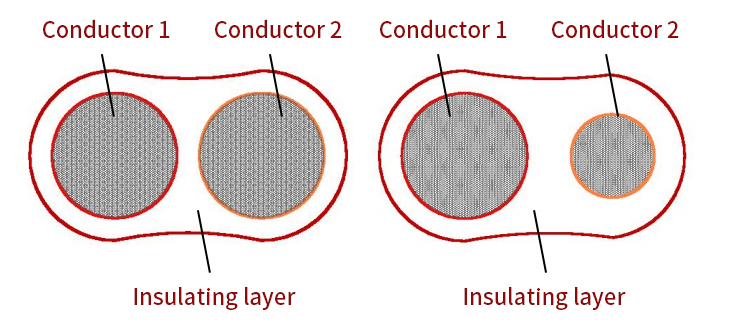

1. Features: Customized specifications and insulation layer varieties, and the surface layer can be coated with self-adhesive layer.

2. Specification range: single line with the same specification but different colors, different specifications and different varieties (single line specification range: 0.03mm-0.500mm).

3. Product application: It is mainly used in high demand double/multi wire parallel wound products, such as special inductors, RF transformers, etc; It can be wound into two/three/five coil communities with different colors and completely consistent resistance/inductance and other parameters, or into two/three/five coil communities with different specifications but identical wire length.

4. The schematic diagram is as follows:

Process flow of enamelled wire

1、 Paying off: On a normally operating enamelled machine, most of the operator's energy and physical strength are consumed in the paying off part. Replacing the paying off reel makes the operator pay a lot of labor. The quality problems and operation failures are easy to occur on the line to line joints. The effective method is to pay off in large capacity. The key of paying off is to control the tension. When the tension is large, it will not only thin the conductor, make the surface of the conductor lose brightness, but also affect many properties of the enamelled wire.

2、 Stretching: The purpose of stretching is to make the conductor which is hardened due to lattice change during the stretching process of the mold heated at a certain temperature, so that the flexibility required by the process can be restored after the molecular lattice rearrangement. At the same time, the residual lubricant and oil stain on the conductor surface during the stretching process can be removed, so that the conductor can be easily painted and the quality of the enamelled wire can be guaranteed.

3、 Painting: painting is the process of coating the enamelled wire paint on the metal conductor to form a uniform paint layer with a certain thickness.

4、 Baking: Like painting, baking is a cyclic process. First, the solvent in the paint solution is evaporated, then cured to form a film, and then the paint is baked. Pollutants will be generated in the baking process, so the furnace shall be discharged immediately. Generally, catalytic combustion hot air circulation furnace shall be used. At the same time, the amount of waste discharge shall not be too large or too small. Because a large amount of heat will be taken away in the process of waste discharge, so waste discharge shall not only ensure safe production and product quality, but also not lead to a large amount of heat loss.

5、 Cooling: The enamelled wire coming out of the oven has high temperature, soft paint film and low strength. If it is not cooled in time, the paint film passing through the guide wheel will be damaged, which will affect the quality of the enamelled wire.

6、 Lubrication: the lubrication of enamelled wire has a great relationship with the tightness of take-up. The lubricant used for the enamelled wire shall be able to make the surface of the enamelled wire slippery, without harm to the wire, without affecting the strength of the take-up reel and without affecting the use of the user. The ideal amount of oil is to make the enamelled wire feel slippery, but no obvious oil can be seen on the hand. From a quantitative perspective, 1 g of lubricating oil can be coated on the surface of 1 ㎡ enamelled wire.

7、 Wire take-up: The purpose of wire take-up is to wrap the enamelled wire onto the spool continuously, tightly and evenly. It is required that the take-up mechanism shall be driven stably, with low noise, proper tension and regular wire arrangement.

After knowing the production process of enamelled wire in detail, do you think it is not easy to produce enamelled wire that meets the standard requirements, because each process step, such as baking or painting, will affect the quality of enamelled wire, and it is also affected by raw materials, quality, environment, production equipment and other factors, so the product quality will be different. Although the quality characteristics and brands of various enamelled wires are different, they basically have four properties, namely mechanical properties, chemical properties, electrical properties and thermal properties.

1.jpg)

1-300x300.jpg)

1-300x300.jpg)

2-300x300.jpg)

-300x300.jpg)