Special conductivity High signal transmission line Alloy enamelled round wire High mechanical properties can be customized

What is alloy wire

1.1 In order to improve the special performance of enamelled wire, alloy wire is enamelled wire whose conductor is made of copper alloy. Alloy wire has special electrical conductivity, mechanical properties, fatigue resistance and excellent bending resistance. To meet the special use requirements of customers, our company provides a variety of alloy enamelled wires. In order to strengthen some characteristics of the wire, we will further process the alloy wires to meet the use needs of customers.

1.2. We can provide copper silver alloy, copper tin alloy, copper nickel alloy, silver plating, nickel plating and other alloy enamelled wires, as well as alloy conductors according to different applications

Type of alloy enamelled wire

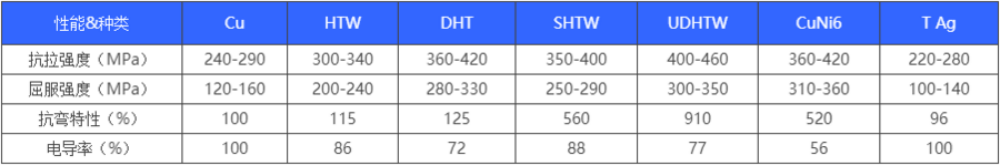

2.1 High tension wire characteristics (HTW, DHT, SHTW, UDHTW):

The high tension wire is a copper alloy self-adhesive enamelled wire specially designed for the application requirements of high mechanical properties. Its models are named HTW, DHT, SHTW, UDHTW; It is used in applications with high requirements for bending resistance and reliability. High tension wire has higher tension resistance, reliability, conductivity and bending resistance than enamelled copper wire.

characteristic:

·The tensile strength is 20-90% higher than that of enamelled copper wire, suitable for high-speed winding, and the solder leg is not easy to break.

·Conductivity>77%.

·The basic insulating layer, self-adhesive layer and enamelled copper wire are the same.

·The performance of direct welding is the same as that of enamelled copper wire.

2.2 High impedance alloy wire characteristics (CuNi6):

The high impedance alloy wire is a copper alloy enamelled wire specially designed for special impedance application requirements, and its model is named CuNi6;

characteristic:

·The impedance value per meter is 6-8 times of that of copper enamelled wire, which is suitable for the generator or special coil used to adjust the Q value.

·The basic insulating layer, self-adhesive layer and enamelled copper wire are the same.

·The performance of direct welding is the same as that of enamelled copper wire.

·Excellent signal transmission characteristics.

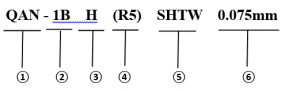

2.3 Product code description:

1. Type code of insulating layer

AN=Weldable UEW

ZN=non weldable PEW

XYN=Non weldable EIW

2. Paint film thickness (1,2,3, refer to IEC and customer standards).

3. Insulation temperature resistance grade

F=155

H=Class 180

S * stands for low temperature soldering tin

4. Type of self-adhesive layer (R self-adhesive layer secondary softening temperature ≤ 130 ℃, R5 self-adhesive layer secondary softening temperature ≤ 160 ℃, R7 self-adhesive layer secondary softening temperature ≤ 190 ℃, C self-adhesive layer is alcohol hot air dual-use, SV self-adhesive layer is heat hardening).

5. Alloy category

HTW=Ordinary high tension wire

DHT=High tension wire

SHTW=super high tension wire

UDHTW=extra high tension wire

6. Nominal diameter of conductor (mm).

Product range: Φ 0.030-0.15mm (AWG52-34)

.jpg)

-300x300.jpg)

1-300x300.jpg)

1-300x300.jpg)

2-300x300.jpg)