High insulation strength Teflon three-layer heat-resistant compression resistance transformer gray self-adhesive coil wireless charger coil

Accuracy of turns

The wrong number of turns will affect the electromagnetic parameters and is not conducive to embedded installation. It is easy to have wrong number of turns when winding coils with more turns. Therefore, many manufacturers will choose to purchase a turn meter or measure the turns manually to solve this problem. Under the 7S production standard, Huaying Electronics has also upgraded the workshop intelligently, using an automatic winding machine

Coil shape control

The shape of the coil shall meet the requirements of the customer, which requires high forming quality of the formed coil, otherwise it will affect the subsequent processing.

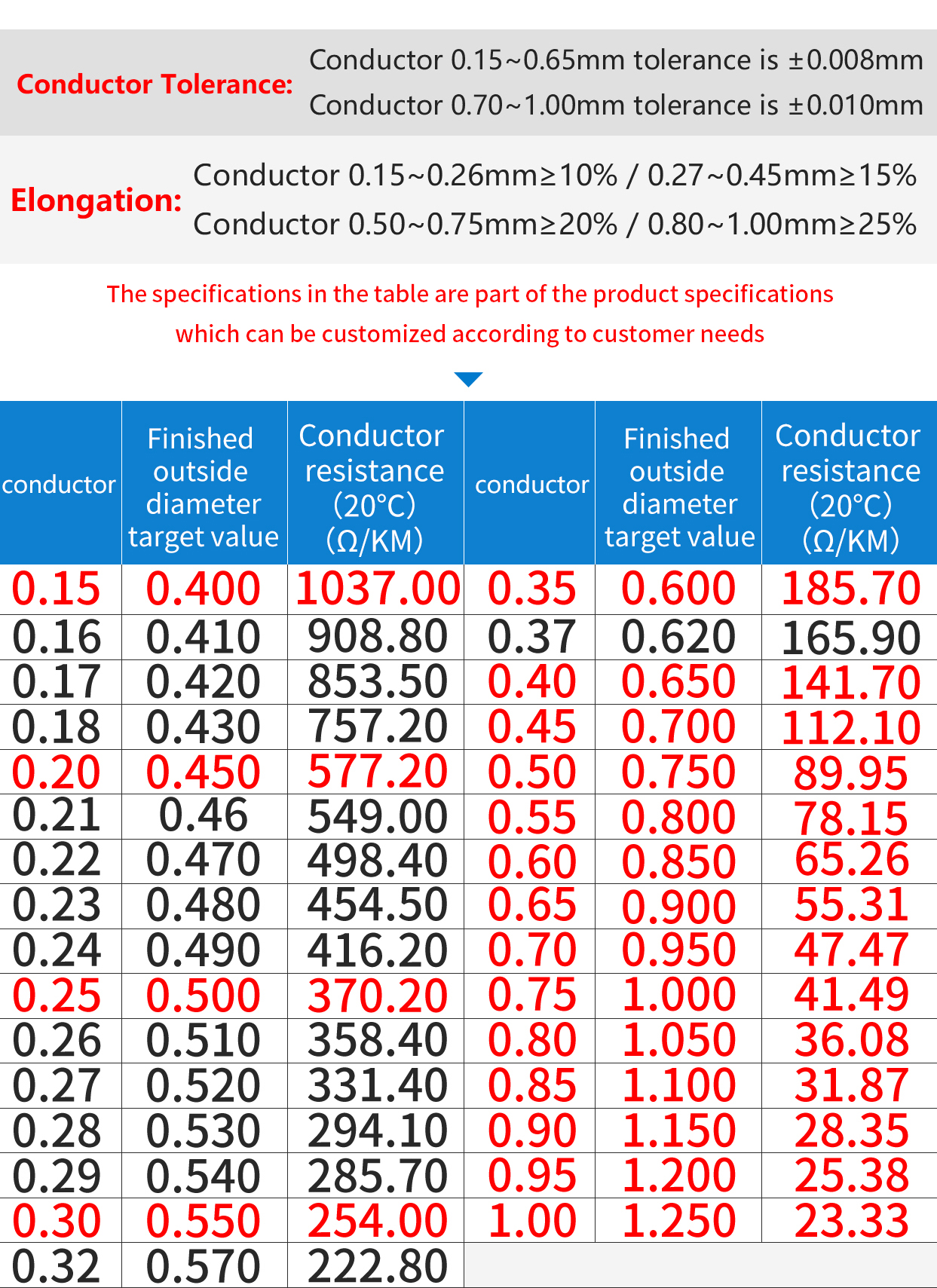

While meeting customer customization needs, although we have been professionals for more than 10 years, we will also be distressed by technical barriers.

Rectangular coils in the market are similar to rectangular coils, such as "oval coils" and "chamfered rectangular coils", which are similar to rectangular coils, rather than real rectangles

The coil is the heart of the transformer and the center of transformer transformation, power transmission and distribution. To ensure the long-term safe and reliable operation of the transformer, the following basic requirements must be met for the transformer coil:

a. Electrical strength. During the long-term operation of the transformer, its insulation (in which Z is important for the insulation of the coil) must be able to reliably withstand the following four kinds of voltage, namely, lightning impulse over-voltage, switching impulse over-voltage, transient over-voltage and long-term operating voltage. Switching overvoltage and transient overvoltage are collectively referred to as internal overvoltage.

b. Thermal strength. The heat resistance strength of the coil includes two aspects: First, under the action of the long-term working current of the transformer, ensure that the service life of the coil insulation is equal to the service life of the transformer. Secondly, under the operating conditions of the transformer, when a short circuit suddenly occurs, the coil shall be able to withstand the heat generated by the short circuit current without damage.

c. Mechanical strength. The coil shall be able to withstand the electromotive force generated by short circuit current without damage in case of sudden short circuit

1-300x300.jpg)

1-300x300.jpg)

2-300x300.jpg)