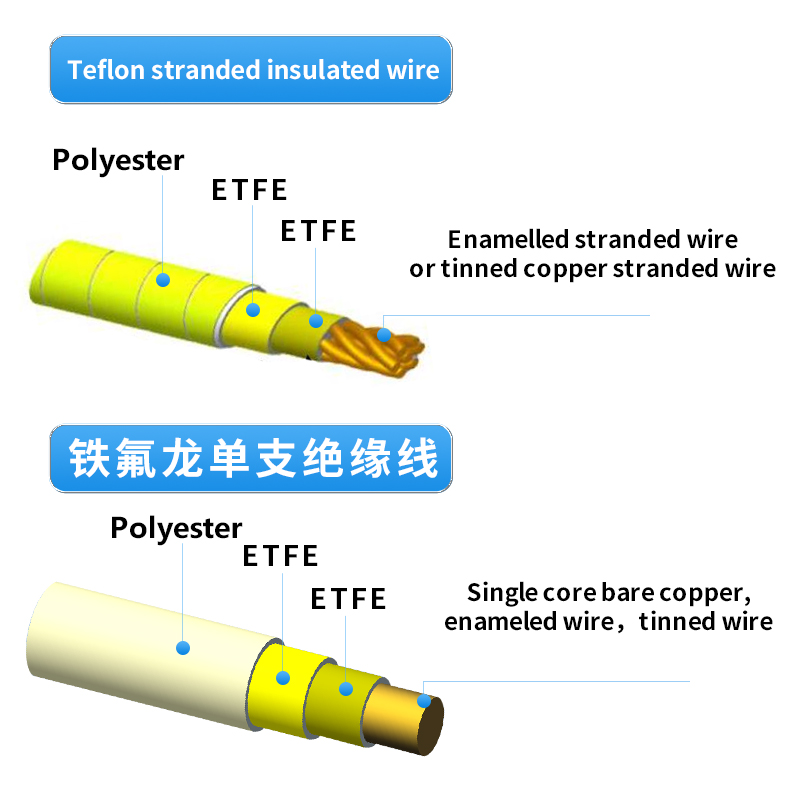

Teflon insulated wire refers to the insulated wire made of fluoroplastic (ETFE), commonly known as fluoroplastic insulation, and wrapped with metal conductors. ETFE is characterized by good processing and molding, balanced physical properties, good mechanical toughness, and excellent ray resistance. The material has the corrosion resistance of polytetrafluoroethylene, overcoming the non adhesion of polytetrafluoroethylene to metals, In addition, its average linear expansion coefficient is close to that of carbon steel, making ETFE (F-40) an ideal composite material with metals.

Characteristics of Teflon insulated wire

1. High temperature resistance: PTFE film has excellent heat resistance. It can withstand high temperature up to 300 ℃ in a short time, and can be used continuously between 240 ℃ and 260 ℃ generally, with remarkable thermal stability.

2. Low temperature resistance - good mechanical toughness; The elongation of 5% can be maintained even if the temperature drops to - 196 ℃.

3. Corrosion resistance - PTFE is widely used in industries requiring high temperature resistance and high viscosity. It can also be used as a super acid with strong Z - fluoroantimonate.

4. Toxic free: It is physiologically inert and can be implanted into the body as an artificial blood vessel and organ for a long time without adverse reactions.

5. Electrical insulation - it can resist 6000 V high voltage.

6. Atmospheric aging resistance: radiation resistance and low permeability: the surface and performance remain unchanged after long-term exposure to the atmosphere.

7. Non combustibility: the oxygen limiting index is below 90.

8. Acid and alkali resistance: insoluble in strong acids, bases and organic solvents.

9. Electrical performance - Teflon has low dielectric constant and dielectric loss in a wide frequency range, and high breakdown voltage, volume resistivity and arc resistance

Post time: Dec-14-2022